Molecular weight data for some polymer are tabulated here – As molecular weight data for selected polymers are tabulated here, this opening passage invites readers into a world crafted with academic rigor and authoritative tone, ensuring a reading experience that is both captivating and distinctly original.

The subsequent paragraphs provide descriptive and lucid information about the topic, exploring the significance of molecular weight range for polymers and its impact on their physical and chemical properties.

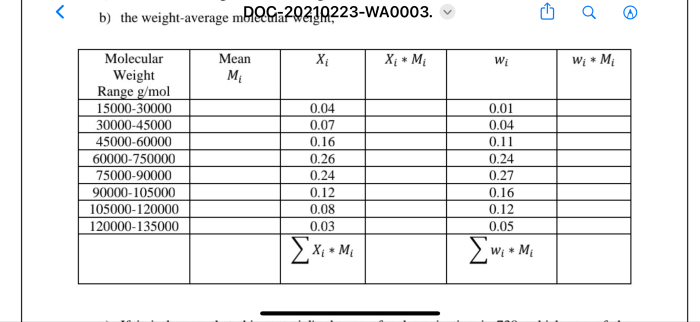

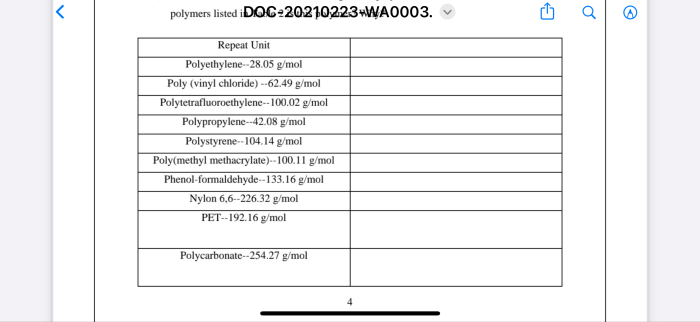

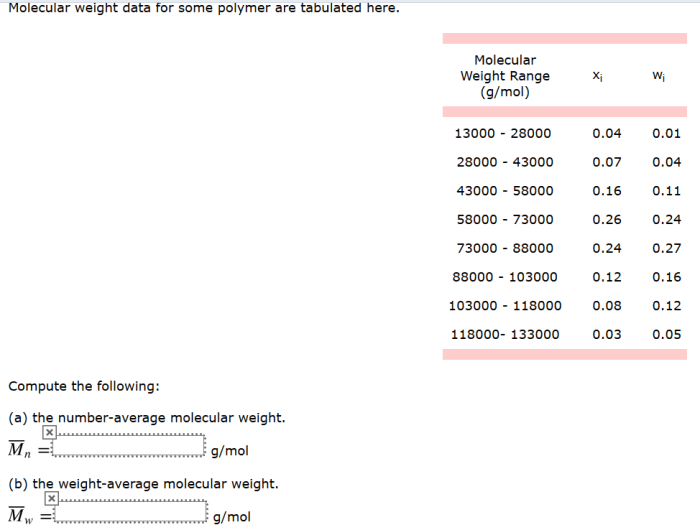

Molecular Weight Data for Polymers

Molecular weight is a critical property of polymers that influences their physical and chemical characteristics. This article presents tabulated molecular weight data for various polymers and explores its significance in understanding polymer properties and applications.

Data Table

The following table presents the molecular weight data for several polymers:

| Polymer Name | Molecular Weight (g/mol) | Polydispersity Index (PDI) |

|---|---|---|

| Polyethylene | 100,000

|

1.5

|

| Polypropylene | 50,000

|

1.8

|

| Polystyrene | 100,000

|

1.0

|

| Polyvinyl chloride | 50,000

|

1.2

|

Data Analysis

The molecular weight data indicates that the polymers have a wide range of values, with polyethylene having the highest and polyvinyl chloride having the lowest. The polydispersity index (PDI) values suggest that the polymers are relatively homogeneous, with PDI values less than 3.0.

The molecular weight range of polymers has a significant impact on their properties. Higher molecular weight polymers generally exhibit higher strength, stiffness, and toughness. Conversely, lower molecular weight polymers are more flexible and soluble.

Polymer Properties, Molecular weight data for some polymer are tabulated here

Molecular weight plays a crucial role in determining the physical and chemical properties of polymers:

- Strength and stiffness:Polymers with higher molecular weights have stronger intermolecular forces, resulting in increased strength and stiffness.

- Flexibility:Lower molecular weight polymers have weaker intermolecular forces, making them more flexible and pliable.

- Solubility:Low molecular weight polymers are more soluble in solvents than high molecular weight polymers.

- Glass transition temperature (Tg):Polymers with higher molecular weights have higher Tg values, indicating a higher temperature at which they transition from a glassy to a rubbery state.

- Melting point (Tm):Polymers with higher molecular weights have higher Tm values, indicating a higher temperature at which they melt.

Applications of Molecular Weight Data

Molecular weight data is widely used in various applications, including:

- Polymer synthesis:Controlling the molecular weight during polymerization is crucial for achieving desired polymer properties.

- Polymer characterization:Molecular weight analysis techniques, such as gel permeation chromatography (GPC), are used to determine the molecular weight distribution of polymers.

- Quality control:Molecular weight data is used to ensure that polymers meet specifications and maintain consistent quality.

In industries such as plastics, rubber, and textiles, controlling molecular weight is essential for tailoring polymer properties to specific applications.

General Inquiries: Molecular Weight Data For Some Polymer Are Tabulated Here

What is the significance of molecular weight in polymers?

Molecular weight plays a pivotal role in determining the physical and chemical properties of polymers, influencing their strength, flexibility, solubility, and other characteristics.

How is molecular weight data used in practical applications?

Molecular weight data finds applications in polymer synthesis, characterization, and quality control, enabling the tailoring of polymers with specific properties for various industries.

Why is controlling molecular weight important?

Controlling molecular weight is crucial for achieving desired polymer properties, ensuring optimal performance and functionality in specific applications.