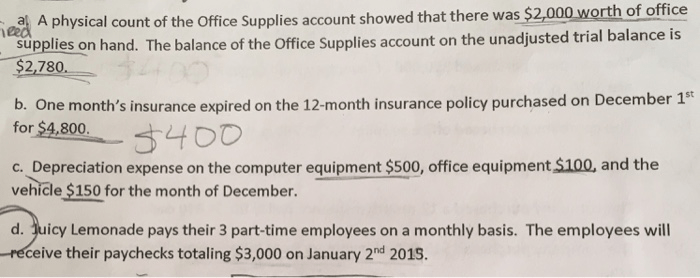

Supplies on hand on may 31 are 5 – Supplies on hand on May 31 are valued at $715, a figure that underscores the critical importance of effective inventory management in any organization. This inventory represents a crucial resource that can impact operational efficiency, cost optimization, and overall supply chain performance.

The composition of this inventory encompasses a diverse range of supplies essential for day-to-day operations, including raw materials, finished goods, and maintenance equipment. Understanding the significance of these supplies and implementing sound inventory management practices are key to ensuring business continuity and maximizing value.

1. Current Supplies on Hand

Having $715 worth of supplies on hand as of May 31st indicates a prudent level of inventory management. This inventory serves as a buffer against unexpected demand fluctuations or supply chain disruptions.

Potential reasons for maintaining this level of supplies include:

- Anticipating increased demand during the upcoming quarter.

- Preparing for potential supply chain disruptions due to seasonal factors or geopolitical events.

- Ensuring availability of essential items to meet customer needs.

Examples of supplies that may be included in this inventory:

- Raw materials for production

- Finished goods ready for sale

- Spare parts and maintenance supplies

2. Inventory Management Practices

Effective inventory management practices are crucial for optimizing supply chain performance. Best practices include:

- Regular inventory audits to ensure accuracy and prevent stockouts.

- Cycle counting to identify and correct inventory discrepancies.

- Optimizing inventory levels to minimize waste and maximize efficiency, using techniques such as ABC analysis and just-in-time inventory management.

3. Forecasting and Planning

Forecasting future supply needs is essential for proactive inventory management. Methods include:

- Time series analysis using historical data and trends

- Demand forecasting based on market research and industry projections

A supply plan aligns with anticipated demand, considering lead times, safety stock levels, and potential disruptions.

4. Cost Optimization

Strategies for optimizing supply costs include:

- Negotiating with suppliers for better pricing and terms

- Exploring alternative sourcing options to reduce costs

- Implementing cost-saving measures without compromising quality, such as bulk purchasing or vendor consolidation

5. Supplier Relationships

Strong supplier relationships are vital for supply chain continuity and performance. Best practices include:

- Evaluating supplier performance regularly to identify areas for improvement

- Managing supplier risk by diversifying sourcing and monitoring supplier financial stability

6. Technology and Automation

Technology plays a significant role in streamlining inventory management:

- Inventory management software provides real-time visibility into inventory levels and facilitates efficient inventory tracking

- Automation tools, such as RFID technology and automated inventory replenishment systems, improve accuracy and reduce labor costs

7. Data Analysis and Reporting: Supplies On Hand On May 31 Are 5

Data analysis is crucial for improving inventory management. Key metrics include:

- Inventory turnover ratio

- Days of inventory on hand

- Stockout rate

Regular reporting and data visualization support decision-making and continuous improvement.

8. Continuous Improvement

Ongoing improvement is essential in inventory management:

- Regularly review and assess inventory management processes to identify areas for improvement

- Implement corrective actions to address inefficiencies and enhance performance

- Stay updated with industry best practices and emerging trends to optimize inventory management strategies

Top FAQs

What are the key benefits of effective inventory management?

Effective inventory management optimizes stock levels, reduces waste, minimizes costs, improves customer service, and enhances overall supply chain efficiency.

How can technology enhance inventory management processes?

Inventory management software and automation tools streamline processes, improve visibility, enhance accuracy, and provide valuable data for informed decision-making.

What strategies can organizations employ to optimize supply costs?

Negotiating with suppliers, exploring alternative sourcing options, and implementing cost-saving measures without compromising quality are effective strategies for optimizing supply costs.